DEC.SRU™

Solvent Recovery Unit | Solvent Recovery Plant | Solvent Recovery System

SRU | SRP | SRS

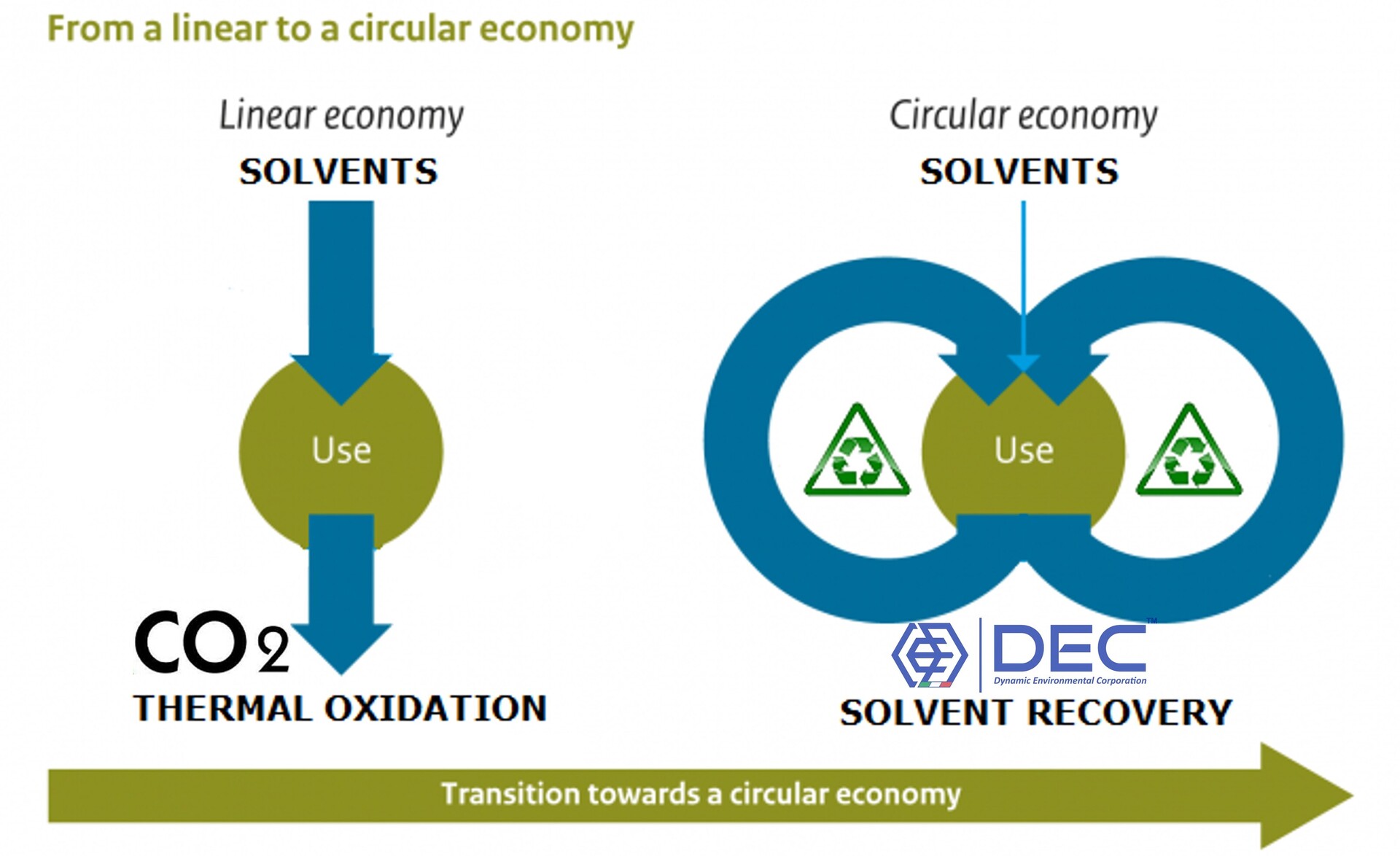

Solvent Recovery Units (DEC.SRU™), also known as Solvent Recovery Plants, SRP or Solvent Recovery Systems, SRS, are employed in solvent-based manufacturing processes to control air emissions of solvents (VOCs Volatile Organic Compounds and HAPs, Hazardous Air Pollutants from solvent-laden air or vapor) to comply with global, regional and local environmental regulations and directives.

Recovering these solvents for direct reuse, at a fraction of the purchasing cost, will generate important savings (ROI).

|

|

A Solvent Recovery Unit (DEC.SRU™) (SRP | SRS) consists of a specifically designed DEC.SBC™ static concentrator, coupled with an “in-situ” regeneration process.

A static concentrator employs an DEC.AAS™ • adsorbent to adsorb contaminants (VOCs, solvents) from a gas (SLA, solvent-laden air): selected adsorbent shall be a highly porous material with a large surface area, which makes it an effective adsorbent (typically DEC.ACA™ • activated carbon). The adsorbent is packed into a series of adsorbers, and the gas stream is passed through the adsorbers in sequence. As the stream passes through each adsorber, contaminants are adsorbed onto the adsorbent. Once an adsorber is saturated with contaminants, it is taken offline and regenerated. Regeneration involves both mechanical and thermal energy to be delivered to the adsorbent: these combined energies will drive off the adsorbed contaminants (known as desorption). These contaminants are then driven through a condenser (heat exchanger), for direct condensation and reuse. Once desorption cycle is completed, the adsorbent will be ready for the next adsorption cycle.

Here is a simplified overview of how DEC.SRU™ (SRP | SRS) works:

The following desorption technologies & regeneration processes are available:

* DEC.RSG™ - activated carbon solvent recovery, TSA inert gas (nitrogen, N2) regeneration;

* DEC.RSV™ - activated carbon solvent recovery, TSA steam (H2O) regeneration;

* DEC.RTV™ - activated carbon solvent recovery, T+VSA inert gas (nitrogen, N2) vacuum regeneration;

* DEC.RSC™ - solvent recovery, direct condensation.

DEC Solvent Recovery Units (SRUs) are available in both skid modular layout (DEC.SMS™ • Smart Modular Systems, pre-built and pre-tested at our workshops) or in full customizable version (DEC.CBS™ • Custom Built Systems, with on-site erection).

If you are looking for a reliable and efficient solvent recovery unit, DEC.SRUs™ (Solvent Recovery Units) are the right and best option: DEC.SRUs™ are the most advanced and reliable Solvent Recovery Units on the market, with processes, configurations and options to meet the needs of different applications, present and future challenges.

Feel free to contact DEC: we can help you assess your needs and recommend the best SRU for your operation.