DEC.N2G™

nitrogen generators

Nitrogen (N2) plays a crucial role in our activated carbon solvent recovery units (SRUs) by serving as the regeneration (desorption) media (DEC.RSG™ and/or DEC.RTV™ processes. However, in certain regions, the availability and convenience of liquid nitrogen (DEC.N2L™) can be a challenge: as a result, we have implemented on-site nitrogen generation solutions (DEC.N2G™) to supply our solvent recovery units (SRUs). Our DEC.N2G™ on-site nitrogen generators utilize a specialized adsorbent called DEC.CMS™ • carbon molecular sieves and leverage the Pressure Swing Adsorption (PSA) process.

DEC.N2G™ | nitrogen generators, carbon molecular sieves | PSA

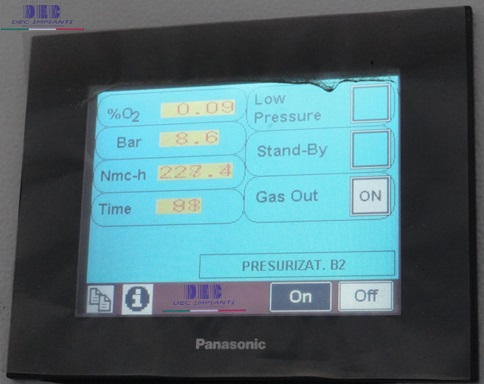

By employing state-of-the-art analytical controls, our systems have the capability to produce nitrogen of exceptionally high purity. If required, we can achieve purity levels of up to 99.999%. Moreover, our nitrogen generation systems offer outstanding reliability, low operating costs, and an extended operational lifespan.

DEC.N2G™ nitrogen gas generators separate nitrogen from air: air entering the generator consists of 21% oxygen (O2) and 78% nitrogen (N2). The gas separation process preferentially adsorbs oxygen over nitrogen, using DEC.CMS™ • carbon molecular sieves, thus enabling the N2 to pass through as a product gas at pressure, while oxygen is adsorbed and separately discharged, during regeneration process.

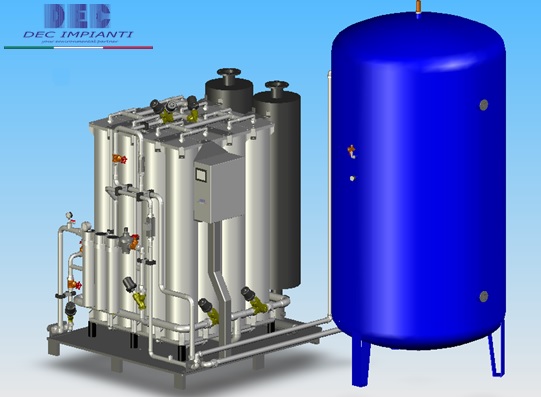

DEC.N2G™ nitrogen gas generators are conceived in a modular design, skid mounted, allowing standardized layout and constant performances: typically, higher will be the demanded throughput, higher will be the numbers of installed modules.